|

HFStuart

|

|

« on: November 20, 2011, 07:24:54 PM » |

|

Before I bought it my Spider hadn't run in the last five years. I got it back into decent condition but only gave the engine a basic once over. I've put over a thousand miles on it over the summer (not much, but good going for me!) and the engine is obviously tired. Oil pressure is dropping slowly and it burns 1L oil per 250 miles - a combination of hard valve stem seals and worn rings I expect.

The good news is I have the engine from my black spider that I rebuilt a few years ago and that made 120bhp+ the one time I had it on the rollers.

I could just put it in as it is.....on the other hand we all like to fiddle. So the plan is:

Avanti Head (thanks Eric) with the larger inlet valves

2x45 DCOE

Mapped ignition using ford EDIS

Slightly increased compression ratio

4-2-1 Manifold and custom exhaust but keeping the swans neck end piece

Target is a very flexible 160bhp with a 7,000 rpm limit

I started in earnest today which meant getting the block from the shed to the garage. I do not recommend lifting a fully dressed T/C block into a wheelbarrow! Even with the flywheel off it was a little heavy side.

The good news is the pistons and bores are like new so I just need to measure the compression ratio as is and check the crank endfloat and then the crank will be comming out to go to Guy Croft with the flywheel and oilpump while either the head or block will get skimmed to get the CR where I want it.

No doubt it will take me longer than I expect but I'll post up here occasionaly to let you know how I'm getting on.

Stuart

|

|

|

|

|

Logged

Logged

|

|

|

|

|

75coupe

|

|

« Reply #1 on: November 21, 2011, 07:40:20 AM » |

|

Make sure you post plenty of pics Stuart, good to see another "Twink" being tuned....what cams are you going to use, or are you going to stick with std?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

WestonE

|

|

« Reply #2 on: November 21, 2011, 08:18:21 AM » |

|

Stuart

Good to see the bits being put to good use. With cast pistons and your objective I suggest a GC 3A cam for the inlet side standard exhaust cam. This should give a fat torque curve and meet or exceed your BHP targets. I would skim the block to raise the compression but check piston to valve clearance with plasticiene in the valve cut outs with the cam you are using so you know how much you can remove and also whether the valve pockets need any machining. This will normally be number 1 or number 4.

Eric

PS Darren Cooksey went this route on his Montecarlo last year so have a look at his posts for the results.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

HFStuart

|

|

« Reply #3 on: November 21, 2011, 10:03:00 PM » |

|

Thanks,

I will be posting pics !

Cams I'm undecided at the moment but either std or a GC inlet. Anything else is pobably overkill for my needs and might not work that well given I'll not be going more than 9.8:1 on the CR

Skimming the block is the ideal option but today's measurement show I only have 0.64mm to play with before the pistons are level with the top of the block and that's assuming the pistons come no further up at 7,000 rpm. It's an 84.8 bore so the pistons are VERY close to the fire rings on the head gasket. I might have to take some from the block and a little from the head too but we'll see what the combustion chamber measurements suggest I need to remove before deciding that.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

HFStuart

|

|

« Reply #4 on: November 28, 2011, 10:41:58 PM » |

|

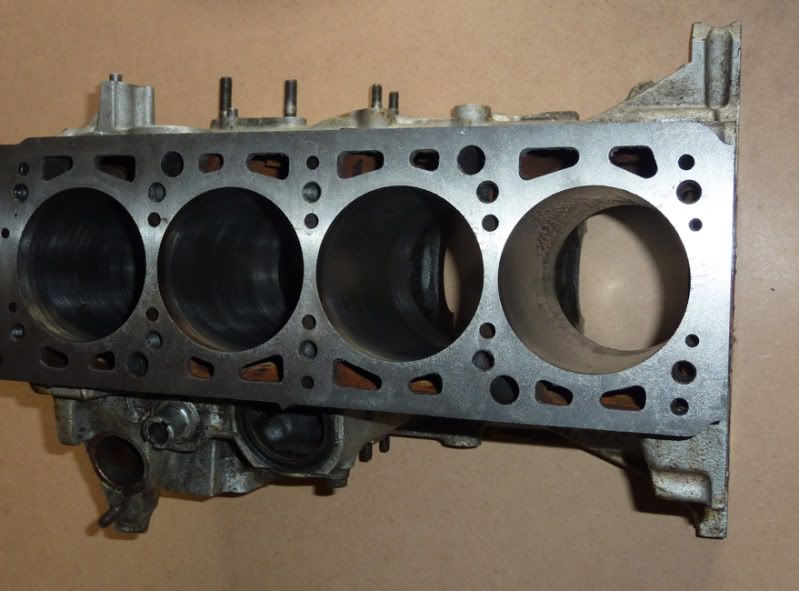

Some progress this weekend and pics of oily bits. It takes a surprising amount of time to fully strip a block - most of the day in fact. Still few problems and everything looks in good nick. First I measured the crank endfloat to make sure it was OK - it is 0.1mm, then I measured the unswept volume in the bore, the volume in the head gasket and the combustion chamber volume using the burette and bit of plastic method. More on this in a bit. Once that was done stripping could start in earnest. The biggest problems were getting the No.3 main bearing cap off and removing the aux shaft pulley. The pulley was tricky as I have nothing to hold it with - I ended up drilling two m6 holes through and putting bolts through them to hold it in place. The bearing cap was more of a challenge - I did it up with a good torque wrench a few years ago - but I needed my 4ft 3/4 drive breaker bar to undo them, the bolt was so tight the bolt head had swaged out at the bottom, razor sharp too as I found out.. God knows why it was so tight. Out with the crank, pistons and everything else to leave me with this   A box of bits for cleaning  and a crank and oil pump to go off to Guy Croft for checking / prepping  All parts look in very good condition but then it had only done a thousand miles or so. Oddly I had put the big end caps on the wrong rods but it didn't seem to have done any harm. Measuring the compression shows that, as it stands it would be 8.7:1 compression ratio, too low I suspect, especially if I want to go for a hotter inlet cam. To get it to 9.5 I need to deck the block 1.1mm. This will mean the piston crown is 0.35mm above the block at TDC. Piston to head clearance will be OK at 0.9mm but the head gasket is a problem. I've two old ones and the fire rings measure 84.75 - 84.85 diameter on both. That's too tight to the pistons which are 84.76mm (the engine is a 84.8mm overbore). The solution is to machine a chamfer on the edge of the piston crown - just over 1mm at a 30 deg angle will do the trick. So my dad will have some homework to do in his workshop! Next steps are to get the block skimmed, the pistons chamfered and the crank, flywheel and oilpump off to GC. In the meantime I've got a pile of bits to clean up and bag and a garage to tidy. Not to mention front hubs to fit, and a hood to sort out. Still it keeps me out of the house. Stuart |

|

|

|

|

Logged

Logged

|

|

|

|

|

rossocorsa

Guest

|

|

« Reply #5 on: November 28, 2011, 11:15:44 PM » |

|

impressive progress I'm a bit jealous as at the moment as I can't really get on with any engine work yet. My garage remains way too dusty but now that almost all welding has been done on the shell I should be able to clean up and start work.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Hawk

|

|

« Reply #6 on: November 29, 2011, 08:37:19 AM » |

|

Good work!

|

|

|

|

|

Logged

Logged

|

|

|

|

|

MattNoVAT

|

|

« Reply #7 on: November 29, 2011, 02:06:42 PM » |

|

Stuart are you going to have the block cleaned and painted?

How long do you think the engine upgrade will take?

|

|

|

|

|

Logged

Logged

|

1981 2000 Coupe S2/FL

1976 1600 Coupe S1

2007 Ypsilon 1.3 Bi-Colori

|

|

|

|

rossocorsa

Guest

|

|

« Reply #8 on: November 29, 2011, 03:23:31 PM » |

|

Stuart are you going to have the block cleaned and painted?

Wire wheel/elbow grease pot of grey paint and a brush is all that should be needed for that |

|

|

|

|

Logged

Logged

|

|

|

|

|

MattNoVAT

|

|

« Reply #9 on: November 29, 2011, 05:30:54 PM » |

|

Just wondering if it was going to be a "showcase" engine

|

|

|

|

|

Logged

Logged

|

1981 2000 Coupe S2/FL

1976 1600 Coupe S1

2007 Ypsilon 1.3 Bi-Colori

|

|

|

|

WestonE

|

|

« Reply #10 on: November 29, 2011, 08:25:22 PM » |

|

Stuart

Having built numerous engines over the years and prepared the blocks on a lot of them it is a job I am very happy to have GC do as his chemical cleaning kit is far superior to anything I can source and he cleans ALL of the oilways threads and bearing surfaces to an outstanding quality for reasonable money for a job with little joy involved in my experience.

Eric

|

|

|

|

|

Logged

Logged

|

|

|

|

|

HFStuart

|

|

« Reply #11 on: November 30, 2011, 08:58:34 AM » |

|

The block was chemically cleaned when I first rebuilt it and internally it's still very good all in needed was a dowsing in brake cleaner and it came up with a nice matt grey finish.

The state it's in now is after about 1,000 miles and 2 years storage - it was painted silver hammerite over bare metal and looked quite tidy, I might try an engine paint this time. Hopfully it will look smart but it won't be a showpiece (sorry Matt!)

I'm not sure how long it will take, I suspect there will be a bit of a pause now while the bits are sent off for machining work. The aim is to have the engine in the car Feb next year.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

HFStuart

|

|

« Reply #12 on: December 08, 2011, 09:46:25 PM » |

|

Update: Crank, flywheel and oil pump are with Guy Croft. All are useable which is a bonus. He hopes to have them all prepped and back to me before the holidays. I've ordered the trigger wheel and sensor mount from http://www.millersmule.com I know I could have done one myself but sod it! I've also ordered the offset manifold from Guy and got an engine gasket set from Austria. Looks like a busy Christmas! |

|

|

|

|

Logged

Logged

|

|

|

|

|

rossocorsa

Guest

|

|

« Reply #13 on: December 09, 2011, 09:21:27 AM » |

|

all sounds good! I popped into Guy Crofts yesterday and picked up a couple of parts the standard of work in there is genuinely amazing and you couldn't meet a more knowledgeable and friendly bloke.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

HFStuart

|

|

« Reply #14 on: January 01, 2012, 01:50:01 PM » |

|

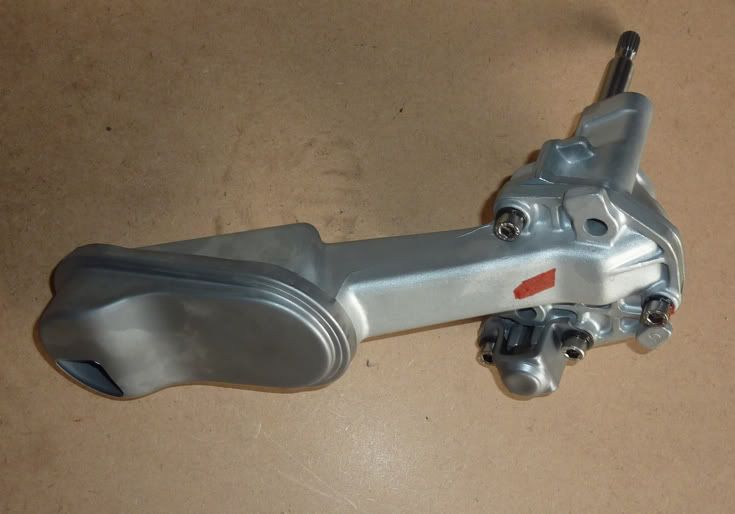

Finally I've found some time to get the garage sorted and the engine bits are back from Guy so I can start the build. For those of you that haven't seen Guy's work the parts look rather better than they did... Crank  Crank prep detail  Oil Pump  Flywheel  The block and pistons are done too   The only issue I've got is the sump. Mine's OK albeit with a weld repair but having spent lot's on the engine work I don't want to wreck it through surge. Does anyone have a good condition sump I could buy and does anyone have any ideas / photos / drawings for sump baffles? |

|

|

|

|

Logged

Logged

|

|

|

|

|

rossocorsa

Guest

|

|

« Reply #15 on: January 01, 2012, 02:03:00 PM » |

|

looking good! Re sump I think I've never seen a beta sump that's not quite heavily dented (to match the subframe!) would also be interested in baffle design although for road use I may well live with it as is (time/money etc...). your oil pump pickup looks a good deal different to the vx one interesting shape to it is it shaped to fit the beta sump?

|

|

|

|

« Last Edit: January 01, 2012, 04:30:29 PM by rossocorsa »

|

Logged

Logged

|

|

|

|

|

WestonE

|

|

« Reply #16 on: January 02, 2012, 08:30:02 PM » |

|

Rosso

The VX pump has a reserve built into the pickup hence the bulge on the VX pumps. I have a fully baffled sump for my Volumetrico build and I thought Mark was supplying kits? somewhere I have photos and card templates, but not at all sure where!!

If you are stuck I can take fresh shots. I believe the baffled sump is vital to long term Beta engine life as I have seen so many wrecked bearings.

Eric

|

|

|

|

|

Logged

Logged

|

|

|

|

|

HFStuart

|

|

« Reply #17 on: January 15, 2012, 08:46:58 PM » |

|

Slow progress this week due to a spate of household disasters I ask you what are the odds of the boiler and shower packing up at the same time??

Anyway the block is up on the engine stand, it's been cleaned degreased and attacked with engine enamel - boring aluminium colour but looks good enough.

Hopfully I can get on with the build now.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

HFStuart

|

|

« Reply #18 on: February 18, 2012, 11:50:07 AM » |

|

A quick update on this.

I found the little ends were worn and had play. Unusual but it had to be sorted so the conrods went off to Gosnays Engineering to be re-bushed and honed to size. Two weeks and £100 later they're back and a much better fit.

In the meantime the car itself has been to SCA in Norwich for them to do wheel alignment and get the corner weights. Having replaced all the hubs, bushes and balljoints I spent £80 to be told "yeah, it was pretty close to be honest" oh well at least I know!

In case anyone is interested The corner weights turned out as follows:

LF 306.5 RF 335.5 (642kg 60.3% front axle)

RL 210.5 RR 212.5 (423kg 39.7% rear axle)

Total 1,065kg

The car is now with the trimmer having a new hood fitted and replacement centre main bearing cap bolts have turned up this morning.

Is there a danger I might actually start to build it this weekend??

Stuart

|

|

|

|

|

Logged

Logged

|

|

|

|

|

75coupe

|

|

« Reply #19 on: February 20, 2012, 11:16:50 AM » |

|

Hi Stuart,

Interesting about the corner weights, I take it this was with everything standard? I plan on having my Coupe weighed after the rollcage has gone in to see what it is like, so good to see some figures, although I realise the spyder is heavier to start with. So nearly 30kg heavier Drivers side front? I suppose it was designed as a left hooker originally.....so with another 70+kg of driver it is quite unbalanced....

regards Ian

|

|

|

|

|

Logged

Logged

|

|

|

|

|